What is industrial remote monitoring?

Industrial remote monitoring is the use of technology to observe and manage industrial processes and equipment from a distance. It involves the collection and analysis of real-time data through sensors, IoT devices, and software to track performance, detect anomalies, and optimize operations. This approach allows for proactive maintenance, improved efficiency, and reduced downtime, as operators can address issues promptly without needing to be on-site. It is commonly used in sectors like manufacturing, energy, and logistics to enhance productivity and ensure safety.

Applications of industrial remote monitoring?

Industrial remote monitoring applications include predictive maintenance, where equipment health is assessed to prevent failures; real-time performance tracking, ensuring optimal operations; energy management, reducing consumption and costs; quality control, monitoring production for defects; supply chain optimization, providing visibility into inventory and logistics; and safety compliance, ensuring regulations are met. Additionally, remote monitoring enhances troubleshooting capabilities, enabling rapid response to issues, and facilitates data-driven decision-making by providing insights into operational trends. Overall, it improves efficiency, reduces downtime, and enhances safety across various industrial sectors.

Different types of industrial remote monitoring?

Industrial remote monitoring encompasses several types, including:

- Environmental Monitoring: Tracks temperature, humidity, and pollutants.

- Equipment Condition Monitoring: Utilizes sensors for vibration, temperature, and pressure to predict maintenance needs.

- Energy Monitoring: Measures energy consumption and efficiency of industrial processes.

- Asset Tracking: Monitors the location and status of equipment and inventory.

- Process Monitoring: Oversees production parameters for quality control.

- Supply Chain Monitoring: Analyzes logistics and stock levels.

These systems enhance operational efficiency, safety, and data-driven decision-making.

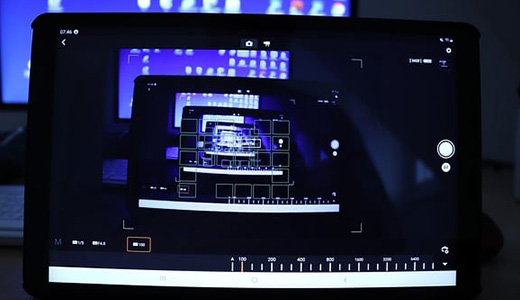

Technology used for industrial remote monitoring?

Industrial remote monitoring typically utilizes IoT (Internet of Things) devices, sensors, and gateway systems to collect real-time data from industrial equipment. This data is transmitted securely over wireless networks, such as LTE, 5G, or Wi-Fi, to cloud platforms for analysis. Advanced analytics and machine learning algorithms process this data to provide insights, alerts, and predictive maintenance. Technologies may also include SCADA systems and remote access software, enabling operators to monitor and control processes from anywhere. Cybersecurity measures ensure data integrity and protection against unauthorized access.