What is remote condition monitoring?

Remote condition monitoring refers to the use of technology to continuously assess the performance and health of machinery or systems from a distant location. It involves the collection of real-time data through sensors and IoT devices, which is then transmitted for analysis. This allows for early detection of potential issues, enabling proactive maintenance and reducing unexpected downtime. Industries like manufacturing, energy, and transportation utilize remote condition monitoring to enhance operational efficiency and extend asset lifespan while minimizing costs and risks.

Applications of remote condition monitoring?

Remote condition monitoring has diverse applications across various industries. In manufacturing, it aids in predictive maintenance, reducing downtime and costs. In healthcare, it enables continuous patient monitoring, enhancing care and timely interventions. In agriculture, it allows for tracking soil conditions and crop health, optimizing yields. Transportation sectors use it for vehicle tracking and maintenance alerts. Additionally, energy sectors monitor equipment like wind turbines and power plants to ensure efficiency and safety. Overall, it enhances operational efficiency, safety, and decision-making across multiple domains.

Different types of remote condition monitoring?

Remote condition monitoring encompasses various types, including:

- Vibration Monitoring: Detects equipment imbalances or failures through vibration analysis.

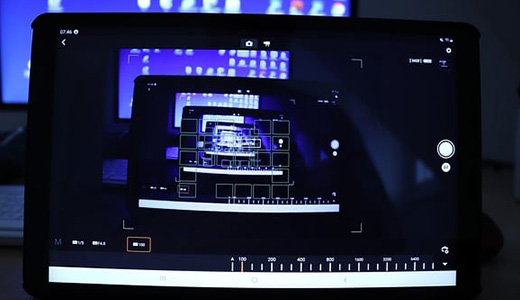

- Thermal Imaging: Uses infrared cameras to identify overheating components.

- Ultrasonic Monitoring: Captures high-frequency sound waves to detect leaks or mechanical issues.

- Oil Analysis: Analyzes lubricant conditions for wear particles and chemical properties.

- IoT Sensors: Continuously track various parameters (e.g., temperature, humidity) via connected devices.

- Telemetry Systems: Transmits data from remote locations for real-time analysis.

These tools enhance asset management, predictive maintenance, and overall operational efficiency.

Technology used for remote condition monitoring?

Remote condition monitoring utilizes various technologies including IoT sensors, wireless communication networks (like Wi-Fi, Bluetooth, and cellular), cloud computing for data storage and analysis, machine learning algorithms for predictive analytics, and mobile applications for real-time updates. These systems collect data from equipment or environments, enabling real-time monitoring and alerts for maintenance or operational issues, enhancing efficiency, reducing downtime, and improving safety.

Advantages and disadvantages of remote condition monitoring?

Advantages: Remote condition monitoring allows for real-time data collection, enabling quick detection of issues and reducing downtime. It enhances safety by minimizing the need for on-site inspections and can lead to cost savings through predictive maintenance.

Disadvantages: It may require significant initial investment in technology and infrastructure. Concerns over data security and privacy arise, along with potential technical issues or system failures. Additionally, reliance on digital platforms can lead to a lack of hands-on experience for technicians.