What is remote equipment monitoring?

Remote equipment monitoring refers to the use of technology and software to observe and analyze the performance and condition of equipment from a distance. It involves collecting real-time data, such as operational metrics and environmental conditions, through sensors and IoT devices. This data is transmitted to a centralized system where it can be monitored, analyzed, and used to predict maintenance needs or potential failures. This approach enhances operational efficiency, reduces downtime, and allows for proactive decision-making, ultimately improving asset management and extending equipment lifespan.

Applications of remote equipment monitoring?

Remote equipment monitoring is utilized across various industries for predictive maintenance, ensuring optimal performance of machinery. It enables real-time data collection and analysis, reducing downtime and operational costs. Applications include monitoring HVAC systems, industrial machinery, fleet management, and energy consumption in smart buildings. Additionally, it aids in environmental monitoring and compliance, remote diagnostics, and enhancing safety by tracking equipment health. Overall, it facilitates better decision-making and improved asset management.

Different types of remote equipment monitoring?

Remote equipment monitoring encompasses various types, including:

- IoT Sensors: Devices that collect data on equipment health, usage, and environment.

- Telemetry Systems: Transmit real-time data over long distances for analysis.

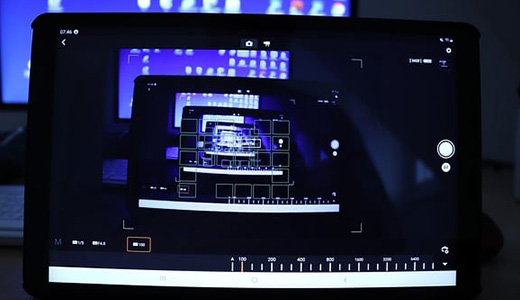

- CCTV and Video Monitoring: Using cameras to oversee equipment operations remotely.

- Predictive Analytics Platforms: Tools that analyze performance data to forecast equipment failures.

- Alerts and Notifications: Systems that send alerts for anomalies or required maintenance.

- Mobile Apps: Applications enabling on-the-go monitoring and management of equipment.

Technology used for remote equipment monitoring?

Remote equipment monitoring often utilizes IoT (Internet of Things) devices, which include sensors to collect operational data such as temperature, pressure, and vibration. This data is transmitted via wireless protocols like Wi-Fi, LoRa, or cellular networks to cloud-based platforms. These platforms analyze the data using machine learning algorithms for predictive maintenance and performance optimization. Additionally, APIs facilitate integration with existing systems, while dashboards provide real-time insights. Security measures like encryption and firewalls are essential to protect sensitive information.

Advantages and disadvantages of remote equipment monitoring?

Advantages: Remote equipment monitoring allows for real-time data collection, enhancing predictive maintenance, reducing downtime, and improving operational efficiency. It enables swift problem identification and intervention, minimizing disruptions.

Disadvantages: Initial setup costs and complexity can be high. There may also be concerns over data security and privacy. Additionally, reliance on internet connectivity can lead to vulnerabilities, and equipment may require routine updates or maintenance to ensure accurate monitoring.