What is remote machine monitoring?

Remote machine monitoring involves the use of technology to track and analyze the performance, condition, and health of machines or equipment from a distance. This process utilizes sensors, IoT devices, and software to collect data in real time, enabling operators to assess operational efficiency, detect potential issues, and perform predictive maintenance. By facilitating timely interventions, remote monitoring helps reduce downtime, optimize resource usage, and extend the lifespan of machinery, ultimately enhancing productivity and reducing operational costs.

Applications of remote machine monitoring?

Remote machine monitoring is widely used in various applications, including predictive maintenance to avoid unexpected failures, energy management to optimize consumption, and operational efficiency to enhance productivity. It facilitates real-time performance tracking for machines in manufacturing, agriculture, and healthcare. Additionally, remote monitoring aids in compliance with safety regulations, enables remote troubleshooting, and provides important data analytics for strategic decision-making. Industries like automotive, aerospace, and utilities leverage this technology to streamline operations and reduce costs.

Different types of remote machine monitoring?

Remote machine monitoring encompasses several types, including:

- Cloud-based monitoring: Utilizes cloud platforms to collect and analyze data from machines in real-time.

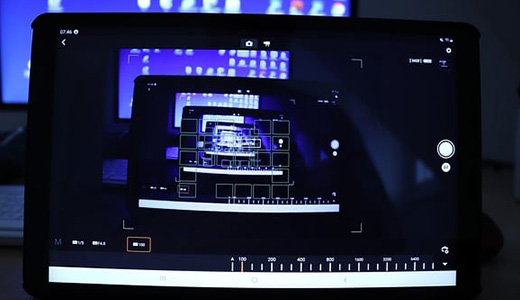

- IoT-enabled monitoring: Leverages Internet of Things devices to track machine performance and health remotely.

- Edge computing: Processes data closer to the machine for faster response times while still allowing remote access.

- Telematics: Combines GPS and onboard diagnostics for fleet and heavy machinery monitoring.

- Remote diagnostics: Enables experts to diagnose issues remotely, often through secure connections.

Each type enhances efficiency, maintenance, and operational decision-making.

Technology used for remote machine monitoring?

Remote machine monitoring utilizes various technologies, including IoT sensors for real-time data collection, cloud computing for data storage and analysis, and edge computing for localized processing. Communication protocols like MQTT and HTTP facilitate data transmission. Monitoring software and platforms provide user interfaces for visualization and alerts. Machine learning algorithms analyze data trends to predict maintenance needs. Additionally, mobile applications enable remote access and control. Overall, these technologies work together to ensure efficient machine performance and reduce downtime.

Advantages and disadvantages of remote machine monitoring?

Advantages of remote machine monitoring:

- Real-time data access improves decision-making.

- Predictive maintenance reduces downtime.

- Cost savings on travel and on-site inspections.

- Enhanced safety by reducing time spent in hazardous environments.

Disadvantages of remote machine monitoring:

- Potential cybersecurity risks.

- Dependence on reliable internet connectivity.

- Initial setup costs and complexity.

- Possible data overload, leading to analysis challenges.