What is remote tank level monitoring?

Remote tank level monitoring is a technology used to track and manage the levels of liquid or granular materials in storage tanks from a distance. This system employs sensors to measure tank levels, which transmit data in real-time to a centralized platform. This enables operators to monitor inventory levels, optimize usage, prevent overflows, and schedule timely refills. Remote monitoring enhances operational efficiency, reduces manual checks, and provides timely alerts for maintenance and management decisions. It's widely used in industries such as oil and gas, water treatment, and agriculture.

Applications of remote tank level monitoring?

Remote tank level monitoring is widely used in various applications, including oil and gas industries for fuel storage management, water treatment facilities for ensuring adequate supply, agricultural sectors for monitoring irrigation tanks, and chemical manufacturing for inventory management. It helps optimize logistics, reduce downtime, minimize overflows, and enhance safety by providing real-time data. Additionally, it supports smart city initiatives by improving resource management and environmental monitoring, leading to better decision-making and cost efficiency.

Different types of remote tank level monitoring?

Remote tank level monitoring can be categorized into several types:

- Ultrasonic Sensors - Use sound waves to measure liquid levels.

- Capacitance Sensors - Measure changes in capacitance due to the liquid level.

- Radar Sensors - Utilize microwave radar to detect levels accurately, even in harsh environments.

- Hydrostatic Pressure Sensors - Measure pressure at the bottom of the tank to derive fluid level.

- Float Sensors - Employ mechanical floats to indicate the level.

- Optical Sensors - Use light reflection to determine the presence of liquid.

Each has specific applications depending on the environment and liquid characteristics.

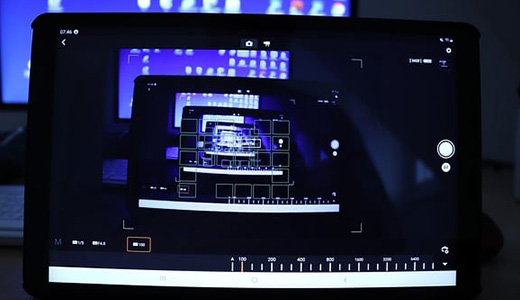

Technology used for remote tank level monitoring?

Remote tank level monitoring typically employs IoT sensors that use ultrasonic, capacitive, or radar technologies to measure fluid levels. These sensors transmit data wirelessly via protocols like LoRa, NB-IoT, or cellular networks to a cloud-based platform. Visualization and analytics software provide real-time monitoring and alerts. Additionally, GPS can enhance location tracking, while energy-efficient designs allow for long-term deployment. Integration with existing systems can provide further insights and automated control.