What is remote tank monitoring?

Remote tank monitoring is a technology that allows for the real-time tracking and management of liquid levels in storage tanks from a distance. It typically uses sensors and IoT devices to collect data on fluid levels, temperature, and other parameters. This information is transmitted to a central system or cloud platform, enabling operators to monitor tank conditions, optimize inventory management, reduce spills, and minimize downtime. The system enhances efficiency and safety, particularly in industries like oil and gas, chemicals, and water management.

Applications of remote tank monitoring?

Remote tank monitoring has various applications across industries, including:

- Oil and Gas: Ensures efficient fuel distribution and leak detection.

- Water Management: Monitors reservoir levels to optimize supply.

- Agriculture: Tracks irrigation tanks for efficient water use.

- Chemical Storage: Maintains safety by monitoring dangerous substances.

- Wastewater Treatment: Monitors sludge levels and prevents overflow.

- Supply Chain Management: Enhances inventory tracking and reduces logistics costs.

These applications improve operational efficiency, safety, and environmental sustainability.

Different types of remote tank monitoring?

Remote tank monitoring typically includes several types:

- Ultrasonic Sensors: Measure liquid levels using sound waves.

- Capacitance Sensors: Detect changes in capacitance due to liquid presence.

- Float Switches: Utilize floats to trigger alerts at specific levels.

- Radar Sensors: Use microwave signals for accurate level measurement.

- Pressure Transducers: Measure pressure variations to infer liquid levels.

- Wireless IoT Solutions: Provide real-time data via connectivity and cloud platforms.

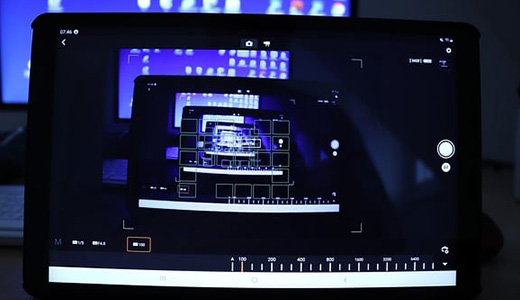

- Visual Inspections via Drones: Offer aerial monitoring capabilities for tank condition assessments.

These technologies improve operational efficiency and safety.

Technology used for remote tank monitoring?

Remote tank monitoring typically utilizes a combination of IoT sensors, wireless communication technologies (like cellular, LoRaWAN, or satellite), and cloud-based data analytics platforms. Sensors measure parameters such as liquid levels, temperature, and pressure, transmitting this data in real-time to centralized systems for monitoring and analysis. Advanced solutions may incorporate GPS for location tracking, as well as machine learning algorithms to predict maintenance needs and optimize operations. These technologies enhance efficiency, reduce downtime, and improve safety in managing tank inventories.

Advantages and disadvantages of remote tank monitoring?

Advantages of Remote Tank Monitoring: Increases efficiency by providing real-time data, reducing manual checks, and minimizing operational costs. Enhances safety by detecting leaks or overflows early. Facilitates accurate inventory management and improves maintenance scheduling.

Disadvantages: Initial investment can be high. Potential cybersecurity risks may expose sensitive data. Dependence on technology could lead to issues if systems fail or require maintenance, and there may be limitations in connectivity in remote locations.