What is remote vibration monitoring?

Remote vibration monitoring involves using sensors and technology to continuously track vibrations in equipment, structures, or industrial activities from a distance. This method helps detect abnormalities, assess equipment health, and prevent failures by analyzing vibration data in real-time. Typically used in industries like manufacturing, construction, and energy, it enables proactive maintenance and enhances safety by addressing issues before they escalate, all without the need for on-site inspections. Data is often sent to cloud-based systems for analysis, allowing for accessible monitoring and reporting.

Applications of remote vibration monitoring?

Remote vibration monitoring is applied in various fields, including structural health monitoring for bridges and buildings, rotating machinery condition monitoring in manufacturing, predictive maintenance for industrial equipment, and earthquake analysis for infrastructure safety. It aids in detecting faults, minimizing downtime, optimizing performance, and ensuring safety by providing real-time data on vibrations, which can indicate potential failures or the need for maintenance. Additionally, it is used in seismic research and monitoring of natural resources, enhancing efficiency and reliability across multiple industries.

Different types of remote vibration monitoring?

Remote vibration monitoring can be categorized into several types:

Continuous Monitoring: Utilizes sensors placed on equipment to collect real-time vibration data continuously.

Periodic Monitoring: Involves scheduled data collection at specific intervals to assess equipment performance over time.

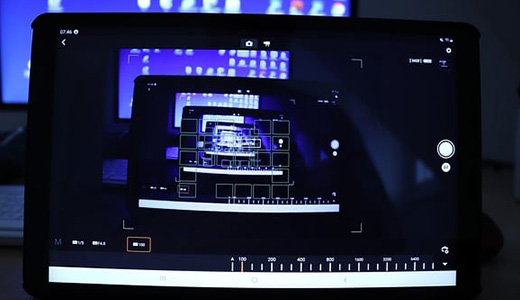

Mobile Monitoring: Uses portable devices to measure vibrations in various locations as needed.

Wireless Monitoring: Employs wireless sensors for data transmission, reducing installation complexity.

Cloud-based Monitoring: Integrates cloud technology for remote data access, analysis, and visualization.

These methods help detect anomalies and prevent equipment failures.

Technology used for remote vibration monitoring?

Remote vibration monitoring utilizes a combination of sensors (such as accelerometers and piezoelectric sensors), data acquisition systems, and wireless communication technologies. These sensors capture vibration data, which is then transmitted via IoT networks or cellular connections to cloud-based platforms for analysis. Advanced analytics and machine learning algorithms process the data to detect anomalies, predict maintenance needs, and enhance overall equipment performance. Visualization tools and dashboards provide real-time monitoring and alerts, improving decision-making in industrial settings.

Advantages and disadvantages of remote vibration monitoring?

Advantages: Remote vibration monitoring allows for real-time data collection and analysis, enabling proactive maintenance and reducing downtime. It enhances safety by monitoring hard-to-reach locations and provides cost savings through optimized maintenance schedules.

Disadvantages: It may involve high initial setup costs and requires reliable internet connectivity. There can be challenges with data interpretation without trained personnel, and potential cybersecurity risks can compromise sensitive data. Additionally, false alarms may occur due to environmental noise, leading to unnecessary interventions.