What is remote monitoring for generators?

Remote monitoring for generators involves the use of technology to track the performance, status, and health of generators from a distance. This typically includes real-time data on parameters such as fuel levels, temperature, voltage, and operational hours. Alerts can be configured for maintenance needs or faults, enabling timely interventions. Remote monitoring enhances reliability, reduces downtime, and optimizes maintenance schedules, ultimately ensuring that generators operate efficiently and effectively in providing backup power.

Applications of remote monitoring for generators?

Remote monitoring for generators enables real-time performance tracking, predictive maintenance, and efficiency optimization. It allows operators to receive alerts for abnormal conditions, monitor fuel levels, and assess operating hours remotely. This technology enhances reliability by detecting issues before failures occur, reducing downtime and maintenance costs. Additionally, it simplifies compliance with regulations by ensuring proper functioning and environmental standards. Remote monitoring systems can also provide insights for better energy management and integration with smart grid solutions, ultimately improving overall operational efficiency and performance.

Different types of remote monitoring for generators?

Remote monitoring for generators includes:

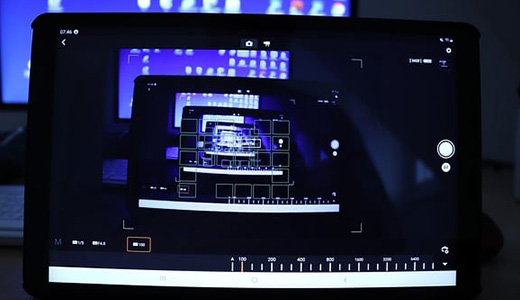

- Telemetry Systems: Use sensors to collect real-time data on performance, fuel level, and operational status.

- IoT Solutions: Connected devices that provide cloud-based monitoring and analytics.

- Mobile Apps: Smartphone apps that allow users to track generator status and receive alerts.

- Web Portals: Online dashboards for monitoring multiple generators and generating reports.

- Alarms & Notifications: Automated alerts for maintenance needs, failures, or abnormal operating conditions.

- Data Loggers: Devices that record and store operational data for later analysis.

Technology used for remote monitoring for generators?

Remote monitoring for generators typically utilizes IoT (Internet of Things) technology, enabling real-time data transmission via cellular, Wi-Fi, or satellite networks. Sensors collect vital parameters like fuel levels, temperature, and operational status, sending this information to cloud platforms. Users access it through dashboards or mobile apps, allowing for prompt maintenance alerts and performance analytics. Some systems also implement GPS tracking for location monitoring and automatic diagnostics to detect issues before they escalate. This technology enhances operational efficiency and minimizes downtime.

Advantages and disadvantages of remote monitoring for generators?

Advantages of Remote Monitoring for Generators:

- Real-time performance tracking and alerts for issues.

- Reduced downtime through proactive maintenance.

- Enhanced operational efficiency and fuel management.

- Access to data from anywhere, improving decision-making.

Disadvantages:

- Initial setup and technology costs can be high.

- Dependence on internet connectivity for effective monitoring.

- Potential cybersecurity vulnerabilities.

- Limited user interaction or hands-on troubleshooting.

Arabic

Arabic Chinese (Simplified)

Chinese (Simplified) Chinese (Traditional)

Chinese (Traditional) Dutch

Dutch English

English Filipino

Filipino Finnish

Finnish French

French German

German Hebrew

Hebrew Hindi

Hindi Italian

Italian Japanese

Japanese Korean

Korean Portuguese

Portuguese Russian

Russian Spanish

Spanish Swedish

Swedish Thai

Thai Turkish

Turkish Vietnamese

Vietnamese